Whole Wheel Refurbishment

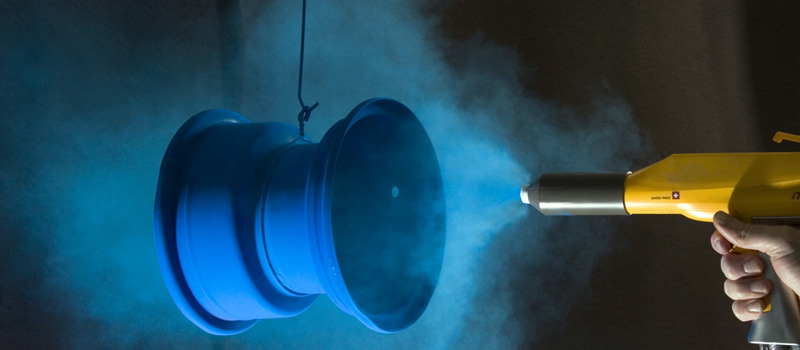

(Powder Coating/Wet Spray Combination) If the wheel is too damaged on the whole, or the damage covers too many areas for a small cosmetic repair to be effective, this process will be used to restore the wheel to its original condition. Specialist equipment is required during this process, giving an exceptional finish which is extremely durable and long lasting.

Previous layers of lacquer and paint are removed to achieve a smooth metal surface on the wheel s. They are then treated with heat to remove any air and a powder coat is applied and cured, followed by any bespoke finishes that the wheels may be having done. A lacquer coat is applied to complete the finish and to protect the wheels against the elements of nature.

s. They are then treated with heat to remove any air and a powder coat is applied and cured, followed by any bespoke finishes that the wheels may be having done. A lacquer coat is applied to complete the finish and to protect the wheels against the elements of nature.

Diamond Cut What is Diamond Cutting?

This process is done in addition to the Whole Wheel Refurbishment process (above). A diamond cut lathe is used to remove micro sections of metal from the wheel to give a diamond cut finish.

Wheels can only be diamond cut so many times, a point which should be considered before applying this process again. Buckled or badly dented wheels will not be dealt with and should be replaced or written off for safety reasons.

SMART Repair

This is a repair to a small area of the wheel to match the existing colour and finish. All tyres are refitted, wheels balanced and then fitted back to your vehicle.